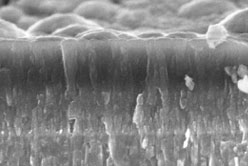

SMT-2267 is a titanium carbo-nitride

coating deposited by the State-of-the-art physical

vapour deposition (PVD) process

SMT-2267 is highly wear resistant and hard

coating providing solutions to lots of applications

like high speed cutting, stamping, punching etc.

SMT-2267 provides higher hardness and lower

co-efficient of friction than titanium nitride (TiN).

Addition of carbon atoms in the TiN FCC crystal

structure enhances wear resistance property and

also reduces friction co-efficient of the coating. The

graded structure improves the impact toughness of SMT-2267 coating that widens the range of its application in various

industries. It is not, however, a replacement for all TiN applications. SMT-2267 is recommended for cutting, punching and

wear applications where moderate temperatures

are generated. SMT-2267 coating displays its

special strengths in tapping and thread forming,

high load punching and metal forming applications.

The coating thickness range is 2-3 µm and can be

tailored as per application

|

|

| SMT-2267 Properties | Features |

| • Hardness: 3200±400 HV | • Excellent wear protection |

| • Oxidation Temp: 500oC | • Excellent Corrosion resistance |

| • Surface Roughness (Ra): 0.2 µm | • Excellent adhesion |

| • Friction coefficient: 0.40 | • Low co-efficient of friction |

| • Wear coefficient:3.5 x 10-14 m2/N | |

| • Coating Structure: Graded/ Multilayer | |

| • Colour: Copper |

| Applications | |

| Hobs and Broaches | Enhances productivity and precision in gear cutting application |

| High speed Cutting | Performs well in cutting alloys steel, stainless steels where moderate temperatures are generated at cutting edges |

| Stamping tool | Enhances the cutting finish of component and life of tool |

| Punches, trimming dies, | Its high hardness prevents edge rounding and improves tool life blanking dies and shearing blades |

| Extrusion dies | Reduces friction and wear at the die surface |

| Die casting | Sheet metal bending and forming. Reduces scoring marks, material sticking, galling |

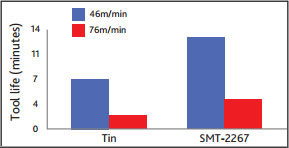

| Coating Performance |  |

| Tool: Carbide endmill Ø11mm | |

| Workpiece: Inconel 718 | |

| Cutting parameters: vc = 50 m/min | |

| Depth of Cut: = 0.5 mm = 50 m/min | |

| Wet machining |

© 2011 SURFACE MODIFICATION TECHNOLOGIES - All Rights Reserved

Powered by G2 Media